Digital monitoring of high die support safety

Digital monitoring of high die support safety

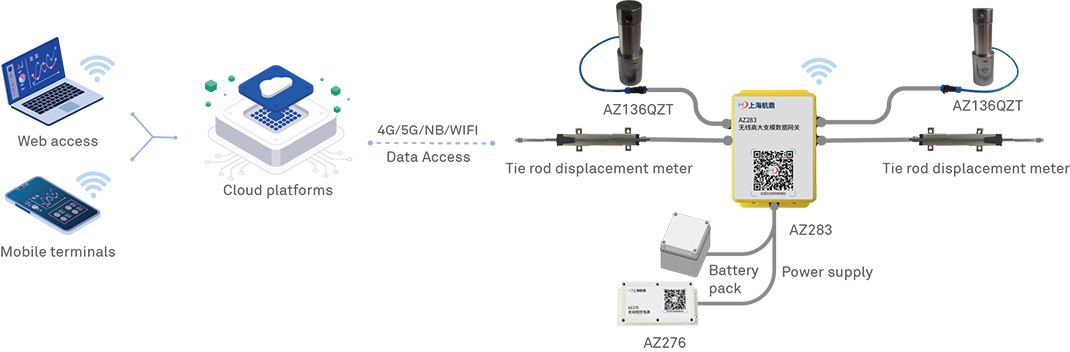

wireless digital acquisition and real-time monitoring; The sub-mother and sub-assembly method directly replaces the standard vertical pole, and the installation is quick and convenient; A single gateway for high-speed monitoring of axial force, tilt, temperature and displacement of high-support dies. Recyclable.

Note: If you need high-frequency real-time monitoring data, you can choose solar panels for power supply.

Hardware

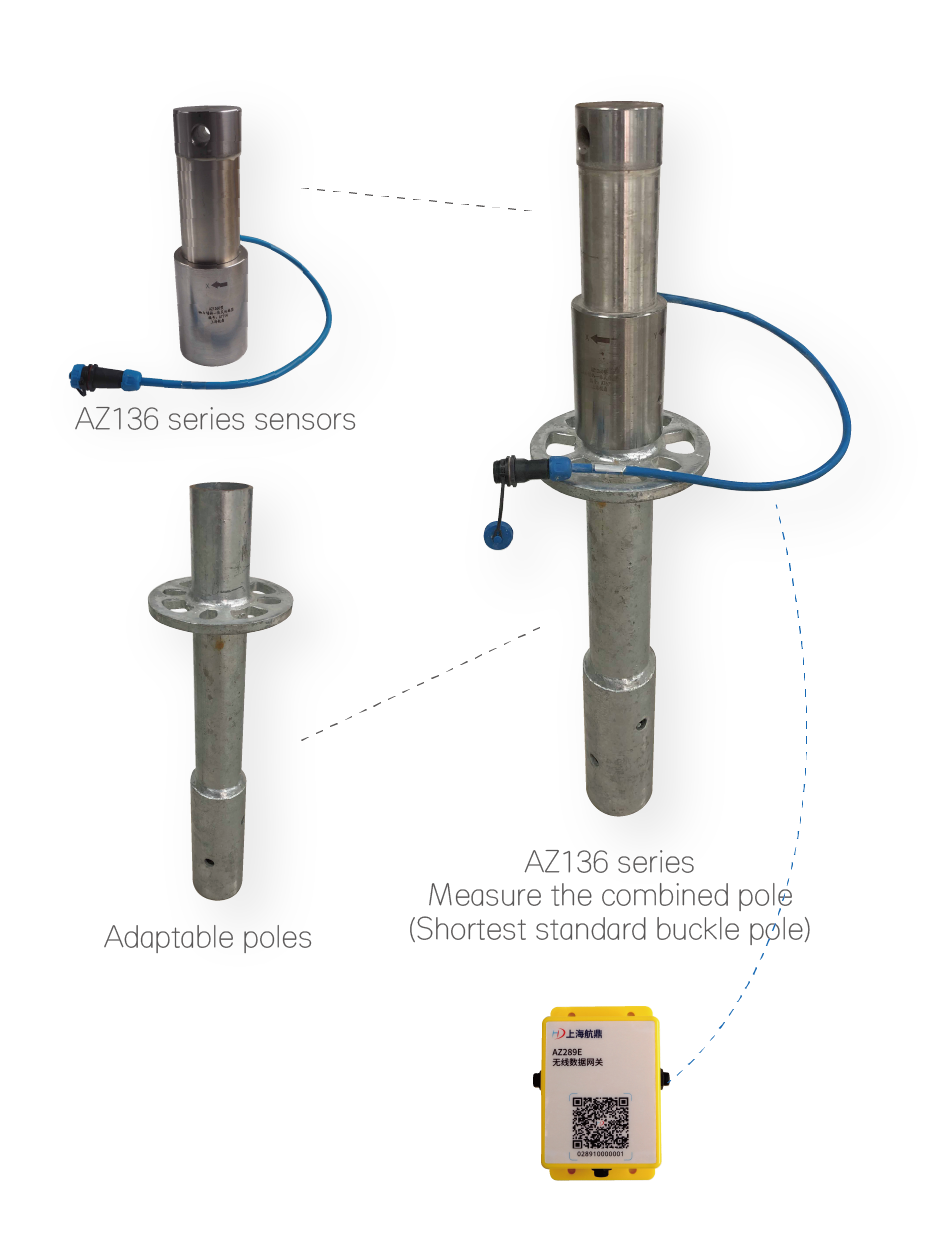

TILT AXIAL FORCE ONE-PIECE SENSOR

- Dimensions: Φ 60 x 200 mm

- High degree of integration, simple and convenient installation

- Real-time, accurate and reliable perception of axial force, inclination and temperature of the pole

- The site is adaptable, can be recycled, and the comprehensive cost is low

- Stainless steel structural parts, cylindrical design, high strength, protection of built-in sensors

- The length is the smallest unit module upright rod of the standard disc buckle bracket, which can be used as the shortest standard upright rod in the high formwork support system

- IP68 protection level, suitable for field work environment

Wireless tall mode data gateway

- Dimensions: 147 x 90 x 51 mm

- Power supply, collection and transmission are integrated

- Support 3-channel displacement sensor acquisition

- It can be cascaded and powered via a data bus

- 4G/WIFI wireless communication mode is optional

- Ultra-low power consumption, fully built-in battery

- Directly connected to 6~30W solar panel for power supply, sustainable work

- IP67

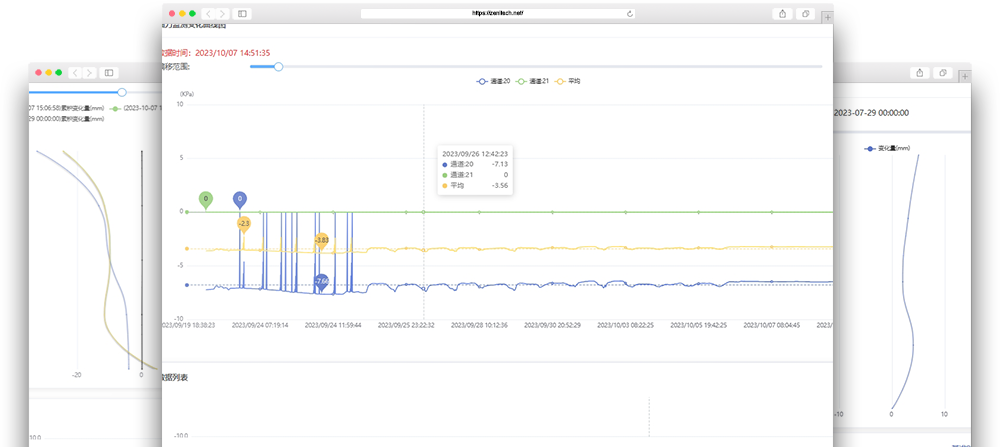

Software

Electronic map + Beidou positioning + cloud computing

Application cases

Safety monitoring project of high formwork of a hospital building in Ningbo